Food Processing

The Australian food processing sector is the largest in the manufacturing industry, employing over 192,000 people. Using the right amount of water in food processing will result in cost savings and environmental benefits.

- The Australian food-processing sector is the largest in the manufacturing industry, employing over 192,000 people. It has an annual turnover of $80 billion and is one of the fastest growing manufacturing sectors in the country.

- Efficient water use is important to the success of the food industry. With this in mind, the Australian Food and Grocery Council signed the first Eco-efficiency Agreement with Environment Australia in 2000. Eco-efficiency is based on the idea of ‘doing more with less’, and efficient water use is an important factor in achieving this.

- Food processing consumes over 241,000 ML of water per year (Water Account Australia, 2004). This equates to 28% of the total water used in the manufacturing sector nationwide, making it the largest water using sector. Within the sector, water use (in litres per kilogram of production) ranges from 1 (for bakery products) to 9 (for meat products).

To reduce water consumption in food processing, companies need to:

- Understand the true cost of water to the operation.

- Accurately measure and monitor water consumption.

- Increase staff awareness and involvement in water efficiency initiatives.

- Install efficient equipment (e.g. spray nozzles).

- Identify and repair leaks.

Water consumption for food processing per kg

In the food industry, water conservation and water recycling issues are closely related to water quality. Often mains water has to be treated before it can be used in processing operations, to ensure a healthy and hygienic product. If lower volumes of water are used, then the cost of treatment is reduced. Furthermore, wastewater treatment offers the opportunity to recycle water for other uses, which can reduce the costs associated with wastewater discharges.

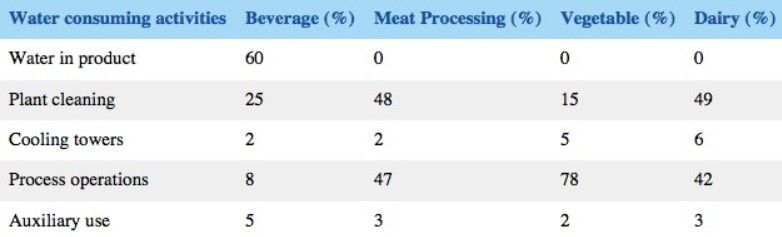

The table below provides a basic breakdown of water use in the food processing industry. Identifying water use is essential to implementing water conservation measures.

Benefits of water efficiency

- Water efficiency in food processing will result in cost savings and environmental benefits.

- Being water-wise will reduce the cost of both mains water supply and wastewater disposal (i.e. potable water and trade waste), as less water will be entering and leaving the site.

- Using just the right amount of water can provide opportunities for developing efficiencies in other areas. For example, using less water may imply a decrease in the amount of water pumped, leading to savings in energy costs and greenhouse emissions.

- Being water efficient can reduce the risk of environmental contamination or pollution, as water efficiency initiatives will lead to less wastewater.